The key input for excellent malt is to ensure the raw material utilised has been dried and stored in the correct conditions. Depending on the growing areas, barleys may be delivered to a maltings straight from a farm at moistures in excess of 14.0% and at varying temperatures. When the raw material is commercially dried, the moistures will be taken down to a level of 12.0%, however the grain temperatures may have risen following the drying process and or may be warmed to help the incoming material to overcome dormancy. It is essential to maintain the Germinative Capacity to over 98%, hence it is key to ensure that temperatures and moistures are controlled with the right timings and environment.

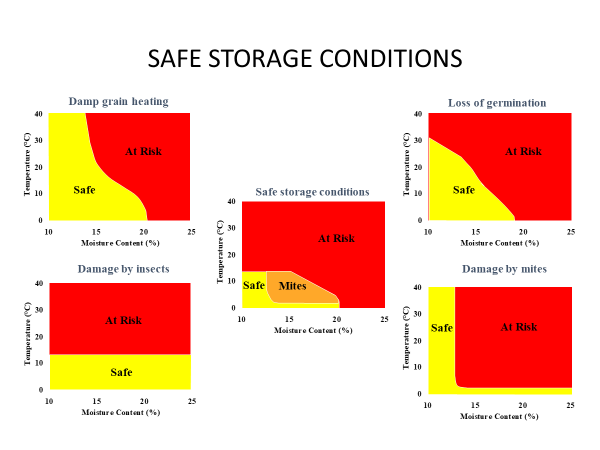

With regards to the diagram below, for long term safe storage the barley must be stored at a temperature below 14°C and a moisture not exceeding 12% moisture, following recovery of dormancy by measuring the Germinative Energy (4cms³) and Water Sensitivity (8cms³). Storing barley at excessive temperatures and moistures may cause spoilage due to storage pest infestation. The most common of these is the Saw Tooth Beetle and Grain Weevil and these can proliferate at high temperatures and moist conditions, so it is essential to manage the bulks of cereal to avoid a down grading of material. It should also be noted that having the ideal storage conditions reduces the risk of the production of Ochratoxin A and introduction of fungi with potential to cause mycotoxins.

Suffolk Automation have identified a software that can automatically monitor the safe storage of grain, so that it maintains its quality for a maximum time period and readily meets the needs of the processing site.

Each storage location containing temperature probes must have a fan in situ, which will be controlled remotely by the use of the ambient temperature and humidity. Providing the climate temperature is below the maximum reading in the storage location and the humidity is below the desired setpoint, the controls will automatically start to make certain the raw material quality is maintained to a high standard and rendered suitable for the set task. Once the product has attained a safe status for storage, the system will automatically monitor and manage the material combined with a manual inspection for laboratory analysis.

Case Study

Case Study

Case Study

Address

Unit 4, Hadleigh Enterprise Park,

Crockatt Road, Hadleigh, Suffolk, IP7 6RJ

Phone

01473 829188